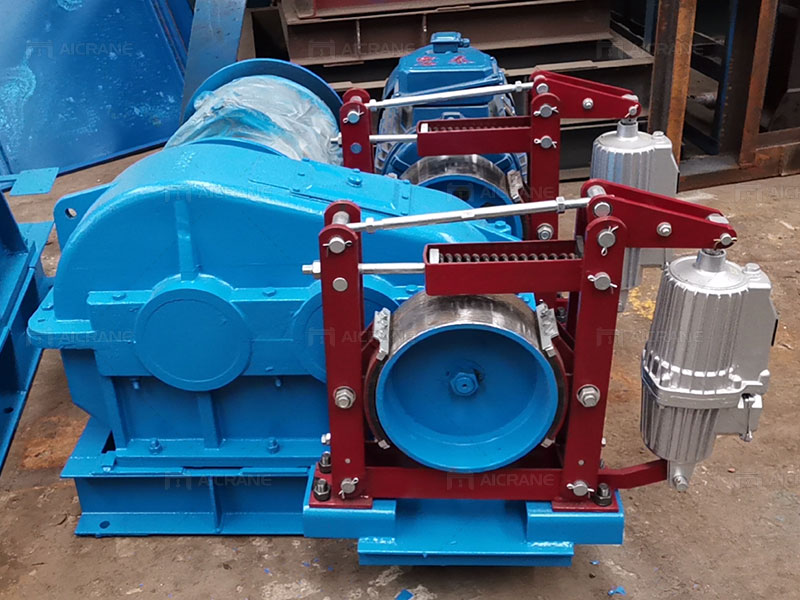

The mining winch is either a hydraulic or electric winch that is used in mines to handle materials such as dragging and carrying minerals. According to different mining requirements and applications, the mine winch and mining underground winch systems are typically customized to deal with harsh conditions to ensure working efficiency and safety.

Introduction To The Underground Mine Winch And The Mining Winch

The mine winch and mining winch is used to handle materials in mines such as copper, gold, iron, zinc, coal, and silver. The mining winch system types include underground mining winches, friction mining winches, shaft sinking mining winches, explosion-proof winches, mining hoist winches, etc.

What Are The Applications Of The Mining Winch And The Mine Winch?

The mining winch and mine winch systems are essential mining equipment that is used in several mines or for mining projects to handle materials such as mineral hoisting, pulling, or for any other mine-related operation.

The pulling and hoisting winches for mines have been fabricated and designed specifically for the exact needs and operating conditions of the mine. This is vital in hydro-power and deep mining industries to enhance productivity, and efficiency, and to improve safety. According to the mining environment and the purpose of the operation, it is possible to obtain well-fitted mining winch systems for a particular application.

The Benefits Of The Electric Mine Winch System

– High Performance

Accurate spotting control, precise operation, stable and reliable performance, backed by a long-lasting service life.

– Outstanding Safety

There are various safety devices included with these mine winch systems that ensure that the operator remains safe. Some of these include remote control and drum guard.

– Durability

The mine winches are made from high-quality materials that provide maximum durability.

– Explosion Proof

The mining winches with an explosion-proof design are used widely for hazardous applications where explosive or flammable gas may be present to maximize safety.

Mine Winches With Explosion Proof Features

When it comes to hazardous applications that usually involve explosive or flammable dust or gas, the design of the winch includes an explosion-proof feature. The explosive-proof electric winches are typically configured with components and parts that include:

– An explosion-proof motor with an explosion-proof level of F and IP66 class insulation.

– Remote control and control cabin. The control cabin features a design that can handle hazardous environments with an explosion-proof enclosure.

– Explosion-proof limit switch that secures the overall operation of a mining winch.

– A specialized paint finish that is used for improved durability, corrosion resistance, and long working life.

Winch Accessories For Customized Mining Winches

Designed for horizontal pulling or vertical hoisting, mining winches are available in various options, and the accessories that match up to specific setups include (but are not limited to):

– Double or single winch drum, a grooved winch drum that improves wire-rope spooling, a guard for the winding winch drum that protects the user.

– Pressure roller that helps to wind the rope onto the winch drum.

– Limit switch that limits the lower and upper stroke.

– Clutch to pull the winches.

– Pendant or wireless remote control.

– Special paint coatings to match up to hazardous applications.