Operating a 100 ton winch requires careful planning, proper training, and adherence to safety protocols. A winch of this capacity is a powerful and versatile piece of equipment used in various industries for lifting, pulling, and moving heavy loads. Whether used in construction, marine applications, or industrial settings, operating a 100 ton winch demands attention to detail, knowledge of equipment specifications, and compliance with safety regulations. Here’s a comprehensive guide on how to operate a 100 ton winch:

Pre-Operational Checks

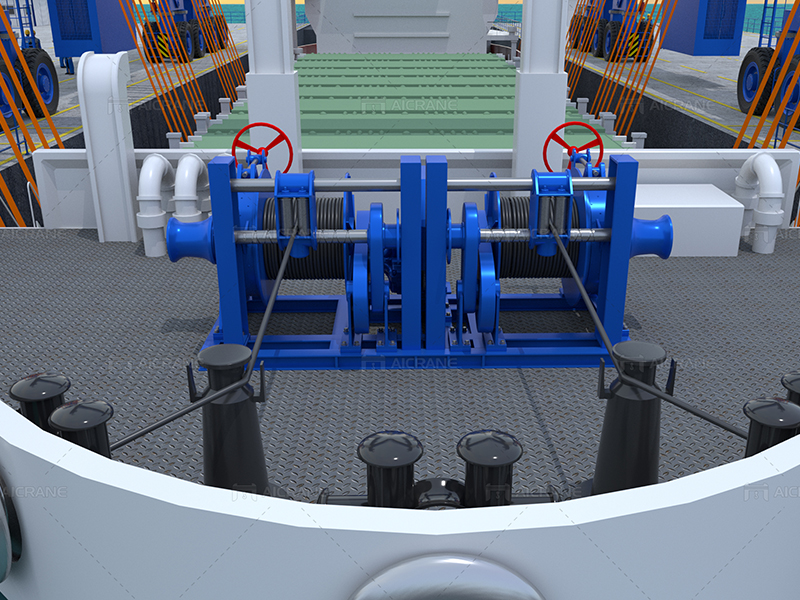

Before using the 100 ton winch, conduct thorough pre-operational checks to ensure the equipment is in good working condition. Inspect the winch, cables, hooks, and accessories for any signs of damage, wear, or malfunction. Check hydraulic or electric systems, controls, and safety devices for proper functioning. Verify that the winch is securely anchored or mounted to a stable surface or structure.

Familiarize with Equipment

Familiarize yourself with the specific features, controls, and capabilities of the 100 ton winch. Review the manufacturer’s operating manual, safety guidelines, and technical specifications to understand the proper operation, load capacities, speed settings, and safety precautions. Identify control buttons, levers, switches, and indicators on the winch control panel or remote control.

Load Calculation and Rigging

Determine the weight and dimensions of the load to be lifted or pulled by the 100 ton winch. Calculate the load capacity, center of gravity, and rigging requirements based on the load’s characteristics. Select appropriate rigging equipment such as slings, cables, chains, shackles, and spreader bars that meet safety standards and load capacities. Ensure proper rigging techniques, angles, and configurations for safe lifting and pulling operations.

Safety Procedures

Prioritize safety during winch operations by implementing safety procedures and protocols. Use personal protective equipment (PPE) such as gloves, helmets, safety glasses, and steel-toed boots. Clear the work area of obstacles, bystanders, and unauthorized personnel. Securely attach warning signs, barriers, and barricades around the operation zone. Establish communication protocols and signals between operators and ground personnel.

Start-Up Sequence

Follow the recommended start-up sequence for the 100 ton winch based on its power source (hydraulic or electric). Activate power supply, hydraulic pumps, or electrical systems according to winch manufacturer instructions. Monitor control panel displays or indicators for system status, pressure levels, and operational readiness. Conduct system checks, such as brake tests, before engaging the winch.

Winch Operation

Engage the winch motor or hydraulic system to begin lifting or pulling the load. Use control levers, buttons, or remote control devices to operate the winch smoothly and precisely. Gradually apply tension or speed to the winch drum to avoid sudden jerks or overloading. Monitor load movement, speed, and alignment throughout the operation. Use brakes, clutches, or stops as necessary to control the winch’s movements.

Load Handling Techniques

Employ proper load handling techniques when using the 100 ton winch. Maintain even tension and alignment during lifting or pulling to prevent load shifting or imbalance. Avoid sudden stops, starts, or changes in direction that could stress the winch or cause load instability. Use taglines, guide ropes, or spotters to assist in load positioning and maneuvering.

Emergency Procedures

Be prepared to respond to emergencies or equipment failures during winch operations. Familiarize yourself with emergency stop procedures, quick release mechanisms, and shutdown protocols. Have contingency plans in place for power outages, hydraulic failures, or unexpected load shifts. Train operators and personnel on emergency response, evacuation procedures, and first aid measures.

Post-Operational Checks

After completing winch operations, conduct post-operational checks and inspections. Inspect the winch, cables, hooks, and rigging equipment for any damage, wear, or fatigue. Check hydraulic fluid levels, electrical connections, and control systems for proper functioning. Securely stow cables, ropes, and accessories in designated storage areas. Clean and maintain the winch according to manufacturer recommendations.

Record Keeping and Maintenance

Maintain detailed records of winch operations, load capacities, maintenance activities, and safety incidents. Keep a log of equipment inspections, repairs, and servicing. Schedule regular maintenance, lubrication, and calibration of the winch components. Follow manufacturer guidelines for servicing intervals, replacement parts, and warranty coverage. Conduct training and retraining for operators on heavy duty winch operation, safety procedures, and best practices.

By following these guidelines and best practices, operators can effectively and safely operate a 100 ton winch, ensuring efficient lifting and pulling operations while prioritizing safety, equipment integrity, and regulatory compliance. Regular training, maintenance, and adherence to safety protocols are essential for successful winch operations in various industrial and construction applications.