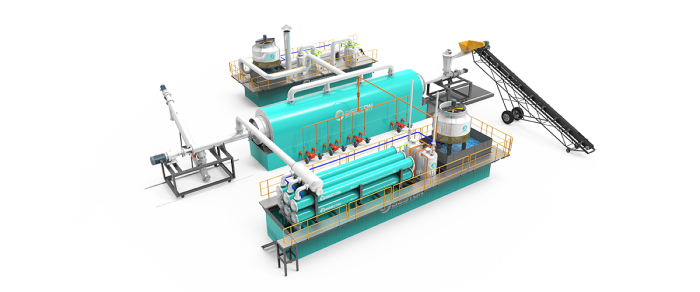

The all-new pyrolysis plant from Beston is unlike others in the industry. It offers buyers the chance to do a very economical and environmentally friendly business. The machine converts the likes of waste tires, plastic, oil sludge, and others into carbon black and pyrolysis oil. Read on as we dive into everything that you’ll need to know about the pyrolysis plant(maquina para pirolisis de plasticos) from Beston.

If you didn’t already know, the plant offers a rather high economical value to your business. In essence, the plant provides a means of recycling waste products into valuable byproducts like steel wire. So, if you’re thinking of investing, this is a great idea.

As previously stated, the plant can recycle a number of products that convert into carbon black and oil. The machine processes the following:

* Oil sludge

* Tire

* Plastic

When there is an influx of these products in the environment, they can easily cause a serious threat to the environment. Hence, the pyrolysis plant is a great disposal idea. The benefits outweigh the cost and everything else associated.

Additionally, there are some great advantages because of the design. Beston(Pirólisis de Beston) has added a third hole in the design. So, there’s the regular gas and carbon black discharger and the newly added cleaning and maintenance port. This adds to the discharger’s life.

One of the biggest things to consider when purchasing a plant is the overall working requirements that you may have. Customer service is provided to ensure that casing and base temperature is always optimal. Hence, the ceramic module is an excellent option.

Unlike other manufacturers, this plant was designed with the environment in mind. This prevents polluted water from being discharged(https://www.bestoneco.com/planta-de-pirolisis/). As such, the water in the inner condenser is separated and doesn’t contain harmful materials.

There’s also an additional chamber that burns combustible gas. The new and improved atomization tower also purifies smoke and the discharge is set to meet the industry emission standards. If for some reason you’re concerned, the plant also guarantees a high level of safety.

The sealed rubber pyrolysis is fitted with an all-new thermometer, a discharge valve, and a pressure gauge. This ensures that the workers on the plant are always protected. Since there’s a portion of the exhaust gas that can not be purified, it is passed through water seals. This allows it to be completely safe.

The company has also added a new generation of heating. This is then combined with both indirect and direct heating. Hence, the production process is not only completely safe but it also saves on the overall fuel consumption.

This line of job has seen some industry disasters. With Beston, some parts of the plant were designed and applied to simply avoid explosions. These include the damping cans, the manifold, and the hydroseal. Beston can create plants(planta de pirolisis en mexico) that are suitable for your every need.