Hydraulic mooring winches play a crucial role in various maritime applications, providing reliable and efficient means of securing vessels to docks or other structures. Understanding the basic components of these winches and their features is essential for ensuring optimal performance and safety during mooring operations. In this article, we will explore the fundamental hydraulic mooring winch components and highlight their key features that contribute to smooth and secure vessel mooring.

Hydraulic Power Unit

At the heart of a hydraulic mooring winch system lies the hydraulic power unit (HPU). This component generates hydraulic pressure required to operate the winch. The HPU consists of a hydraulic pump, motor, reservoir, filtration system, and control valves. Its key features include:

- Robust Construction: HPUs are built to withstand harsh marine environments and provide reliable power supply.

- Variable Flow and Pressure Control: The ability to adjust flow rate and hydraulic pressure allows for precise control during mooring operations.

- Thermal Protection: HPUs often incorporate temperature sensors or cooling systems to prevent overheating.

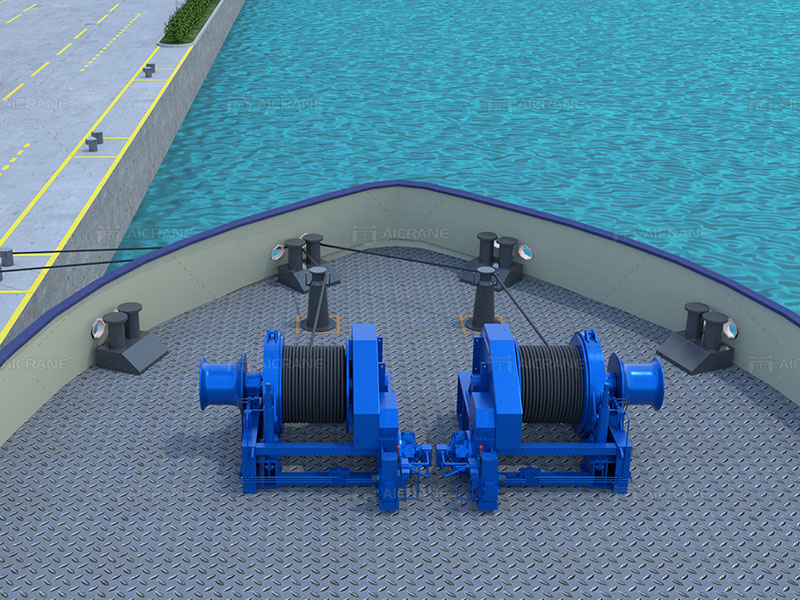

Drum and Drum Brake

The drum is a vital component of the mooring winch where the mooring line or wire rope is wound. It provides storage space for the line while enabling controlled payout and retrieval. Key features of the drum and drum brake include:

- High Load Capacity: Hydraulic mooring winch drums are designed to handle substantial loads and are typically made from durable materials such as steel.

- Grooving and Flanges: The drum’s surface may have grooves or flanges to ensure proper alignment and prevent line slippage during operation.

- Drum Brake System: Integrated drum brakes provide secure holding of the load when the winch is not actively operating. They offer reliable and instant stopping power to avoid unintended movement.

Hydraulic Motor

The hydraulic motor converts hydraulic power into mechanical rotational force to drive the drum and perform the mooring operation. Key features of the hydraulic motor include:

- High Torque and Efficiency: Hydraulic motors provide substantial torque output, allowing for smooth and controlled winding of the mooring line.

- Compact Design: Hydraulic motors are often compact and lightweight, making them suitable for various space-constrained marine applications.

- Reversible Operation: Hydraulic motors can operate in both directions, enabling easy line payout or retrieval as required during mooring.

Control System

The control system is the interface that allows operators to manage and control the mooring winch. It consists of control valves, pressure gauges, flow regulators, and other electrical or electronic components.

Key features of the control system include:

- Ergonomic Interface: User-friendly controls facilitate easy operation, ensuring precise control over line tension and speed.

- Safety Interlocks: Control systems may incorporate safety interlock mechanisms that prevent accidental or unauthorized operation of the winch.

- Automation and Remote Control: Some advanced hydraulic mooring winches feature automation capabilities and remote control options, enhancing operational efficiency and safety.

Conclusion

Hydraulic mooring winches are vital tools in maritime operations, enabling safe and efficient vessel mooring. Understanding the basic components of these winches and their key features helps ensure proper maintenance, operation, and overall performance. The hydraulic power unit, drum and drum brake, hydraulic motor, and control system collectively contribute to reliable and secure mooring operations. By selecting high-quality ship mooring winches with robust components and advanced features, maritime industries can enhance safety, reduce downtime, and streamline mooring processes, ultimately contributing to overall operational excellence.