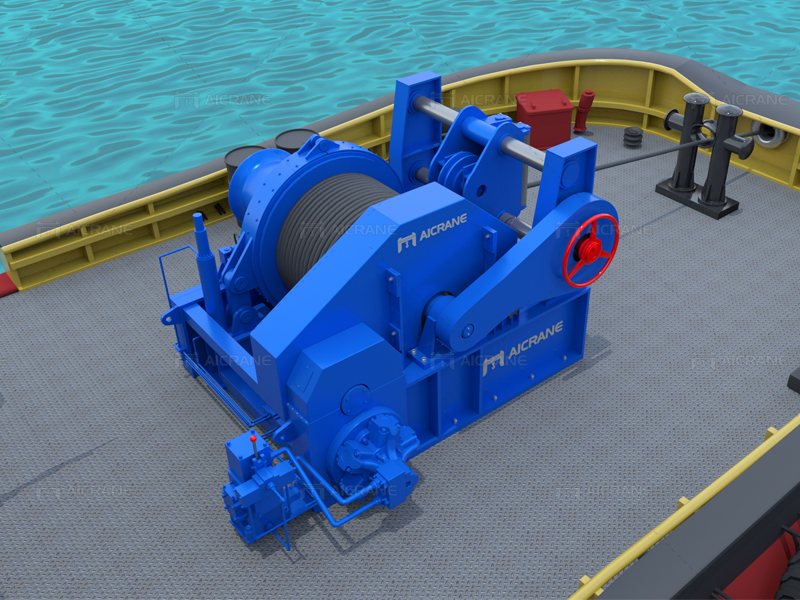

Industrial winches are robust and reliable machines used in various industries for lifting, pulling, and positioning heavy loads. Like any mechanical equipment, winches may encounter issues or require maintenance from time to time. This article presents six essential tips for fixing industrial winches, ranging from basic troubleshooting techniques to more advanced repair considerations. By following these tips, operators can effectively address common winch problems, ensure optimal performance, and extend the lifespan of their equipment.

Understand the Winch Operation and Maintenance Manual

The first step to fixing an industrial winch is to thoroughly review the operation and maintenance manual provided by the manufacturer. This manual contains vital information about the winch’s components, specifications, operating procedures, and troubleshooting guidelines. Familiarize yourself with the manual’s content to gain a comprehensive understanding of the winch’s design and functionality. Pay close attention to sections related to troubleshooting, including symptom descriptions and suggested remedies. Following the manufacturer’s guidelines ensures that repairs are carried out correctly and helps prevent further damage to the winch.

Conduct Basic Troubleshooting

When encountering winch issues, it is essential to perform basic troubleshooting steps before attempting more complex repairs. Start by inspecting the power supply connections and ensuring they are secure and properly connected. Check the control switches, buttons, or levers for any signs of damage or malfunction. Examine the motor and gearbox for loose bolts, worn-out gears, or inadequate lubrication. Inspect cables, ropes, or chains for fraying, kinking, or slippage. By identifying and addressing any obvious or easily fixable issues during basic troubleshooting, you may be able to resolve the problem without extensive repairs.

Replace Worn or Damaged Parts

In the event of worn or damaged parts, it is crucial to replace them promptly. Common components that may require replacement include cables, ropes, pulleys, gears, and bearings. Inspect these parts thoroughly for signs of wear, corrosion, or breakage. Replace any damaged or worn-out components with new, manufacturer-approved parts. Ensure that replacements match the original specifications to maintain the winch’s performance and safety standards. Consider keeping spare parts on hand to minimize downtime in case of emergencies. Regular inspection and proactive maintenance can help identify worn parts before they become critical issues.

Lubricate Moving Parts

Proper lubrication is vital for the smooth and efficient operation of an industrial winch. Over time, lubricants break down, and moving parts may experience increased friction, leading to decreased performance and potential damage. Regularly inspect and lubricate the winch’s motor, gearbox, bearings, and other moving parts as recommended by the manufacturer. Use suitable lubricants based on the winch’s specifications and operating conditions. Apply lubricant where needed, ensuring adequate coverage without over-lubrication, which can attract dust and debris. Proper lubrication not only extends the lifespan of the winch but also reduces wear and tear, minimizing the likelihood of breakdowns.

Check Electrical Components

Industrial winches rely on electrical systems for their operation. If the electric winch experiences electrical issues, it is essential to inspect and address them promptly. Start by checking the power supply connections, ensuring they are secure and free from corrosion. Examine the control switches, relays, and circuit breakers for any signs of damage or malfunction. Test the control panel and wiring for continuity using a multimeter. If any electrical components are found to be faulty, replace them with appropriate replacements recommended by the manufacturer. Engage a qualified electrician for complex electrical repairs or if there is uncertainty about the proper procedures.

Seek Professional Assistance

In some cases, fixing an industrial winch may require specialized knowledge, tools, or expertise beyond what an operator possesses. When faced with complex repairs or unfamiliar issues, it is advisable to seek professional assistance. Winch manufacturers often provide customer support services or have authorized service centers that can offer guidance and repair solutions. These professionals have the necessary experience and resources to diagnose and resolve intricate problems accurately. Engaging experts not only ensures proper repairs are carried out but also reduces the risk of further damage or potential safety hazards associated with incorrect fixes.

Fixing industrial winches requires a systematic approach, including understanding the operation manual, conducting basic troubleshooting, replacing worn or damaged parts, lubricating moving components, checking electrical systems, and seeking professional assistance when needed. By following these tips, operators can effectively address winch issues, optimize performance, and maintain a safe working environment.