Limestone is a versatile and valuable mineral widely used in various industries, including construction, agriculture, and manufacturing. When it comes to limestone crushing, selecting the right crusher or crusher plant is crucial for efficient and cost-effective processing. In this article, we will explore the characteristics of limestone and guide you through the process of choosing the most suitable crusher or crusher plant for your limestone crushing needs.

Understanding Limestone Characteristics

Before delving into the selection of crushers or crusher plants, it’s essential to comprehend the characteristics of the limestone you intend to process.

Firstly, the hardness of limestone can vary significantly, ranging from easily crushable to hard and abrasive. This hardness factor significantly impacts the choice of crusher type and the durability of the crushing components.

Secondly, the presence of abrasive materials like quartz or chert in some limestone deposits can accelerate wear on crusher parts. Identifying such abrasiveness is crucial for ensuring the selected crusher can withstand these abrasive components.

Thirdly, the size of the limestone feed material is a pivotal factor. Large limestone pieces require crushers with different specifications than those designed for finely-grained limestone.

Lastly, the moisture content of the limestone affects handling and processing. High moisture levels may necessitate additional steps, such as drying or pre-processing, to optimize the crushing process.

Choose the Right Type of Crusher Plant

Once you’ve gained a clear understanding of the characteristics of your limestone, it’s time to select the most suitable type of crusher plant. Crushers are the key component of a crusher plant, so let’s start from different types of crushers. Here are some common options and their specific advantages for limestone crushing:

Jaw Crushers:

Ideal for Moderately Hard to Very Hard Limestone

Jaw crushers are well-suited for crushing moderately hard to very hard limestone. Their robust design and strong crushing mechanism make them reliable choices for primary crushing operations. When dealing with tough limestone varieties, such as those with high hardness or abrasiveness, jaw crushers excel in breaking down large limestone pieces into smaller, more manageable sizes.

Excellent for Primary Crushing

Jaw crushers are particularly effective as primary crushers, serving as the initial step in the limestone crushing process. They can handle large limestone blocks, reducing them to a size suitable for further processing by secondary crushers or for immediate use in construction or manufacturing.

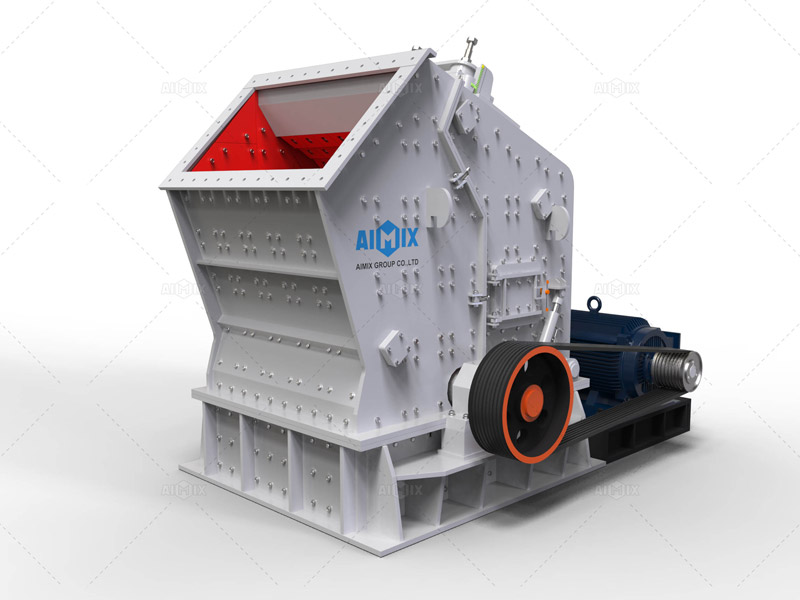

Impact Crushers:

Effective for Processing Medium-Hard to Hard Limestone

Impact crushers are versatile machines capable of effectively processing medium-hard to hard limestone. They excel at crushing limestone and producing cubic-shaped, fine-grained materials. Impact crushers are suitable for both primary and secondary crushing, making them adaptable to various stages of the limestone processing chain.

Produce Cubic-Shaped, Fine-Grained Materials

One of the key advantages of impact crushers is their ability to produce cubic-shaped aggregates, which are highly desirable for construction and manufacturing applications. The fine-grained nature of the crushed limestone allows for precise control over the final product size and shape.

Cone Crushers:

Suited for Crushing Hard and Abrasive Limestone

Cone crushers are an excellent choice when dealing with hard and abrasive limestone. They are designed to withstand the rigors of crushing such materials efficiently. Cone crushers excel at producing well-shaped, uniform-sized aggregates, making them suitable for various applications.

Ideal for Producing Well-Shaped, Uniform-Sized Aggregates

Cone crushers are known for their ability to produce aggregates with consistent shape and size, making them suitable for projects where product uniformity is essential. They are particularly useful for secondary and tertiary crushing stages in the limestone processing workflow.

Vertical Shaft Impact (VSI) Crushers:

Ideal for Shaping and Fine Crushing of Limestone

VSI crushers are specialized machines designed for shaping and fine crushing of limestone. They are particularly effective in producing high-quality, cubical-shaped aggregates that meet stringent requirements for construction and manufacturing applications. VSI crushers are especially useful for reducing abrasive limestone.

Produce High-Quality, Cubical-Shaped Aggregates

The primary advantage of VSI crushers is their ability to produce aggregates with exceptional shape and quality. These cubical-shaped aggregates are highly sought after in the industry for their suitability in various applications.

Combination Crushers:

Combine Different Crusher Types for Versatile Crushing

Combination crushers offer the flexibility to optimize limestone processing by combining different crusher types. They may include jaw crushers for primary crushing, cone crushers for secondary crushing, and impact crushers for tertiary or fine crushing. This versatile approach allows operators to adapt to varying limestone characteristics and project requirements.

Tailored Limestone Processing

Combination crushers provide a tailored approach to limestone processing, ensuring that you can efficiently crush and process limestone in a way that suits your specific needs. By utilizing a combination of crusher types, you can optimize the final product and improve overall operational efficiency. You can invest in suitable limestone crushers with different specifications according to your specific needs.

In summary, the choice of the right crusher plant for limestone crushing depends on your specific limestone characteristics and project requirements. Jaw crushers, impact crushers, cone crushers, VSI crushers, and combination crushers each offer unique advantages, making them suitable for various stages and types of limestone processing. Your choice on different crushers decides your choice on types of crusher plants. Careful consideration of your limestone’s properties and how each crusher type aligns with your goals will help you make an informed decision.

Consider Your Specific Requirements

Choosing the right stationary or mobile crusher plant goes beyond matching the limestone characteristics to the crusher type. Consider the following factors to meet your specific requirements:

1. Crushing Capacity:

Ensure the crusher plant’s capacity aligns with your production goals and anticipated throughput.

2. Final Product Size:

Select a crusher that can consistently produce the desired final product size range for your application.

3. Mobility:

Determine whether a stationary or mobile crusher plant best suits your operational needs and site conditions.

4. Operating Costs:

Evaluate the operational costs, including energy consumption, maintenance, and wear parts expenses.

5. Budget:

Ensure your choice aligns with your budget for both the initial purchase and ongoing operation.

6. Vendor Reputation:

Select a reputable vendor or manufacturer with a history of providing reliable crushing equipment and support.

7. Site Conditions:

Consider site-specific factors, such as available space, power supply, and infrastructure.

By carefully considering these factors, you can make an informed decision when choosing a crusher plant for limestone crushing. This comprehensive approach ensures that your equipment aligns with your specific requirements, budget, and long-term operational goals, ultimately contributing to the success of your limestone processing operation.

Above video shows a kind of crushers for limestone crushing, and you can find more from AIMIX Group Co., Ltd.

In conclusion, choosing the right crusher plant for limestone crushing requires a thorough understanding of the limestone’s characteristics and careful consideration of your specific requirements. By matching the limestone properties to the appropriate crusher type and considering practical factors, you can ensure efficient and cost-effective limestone processing that meets your production goals.